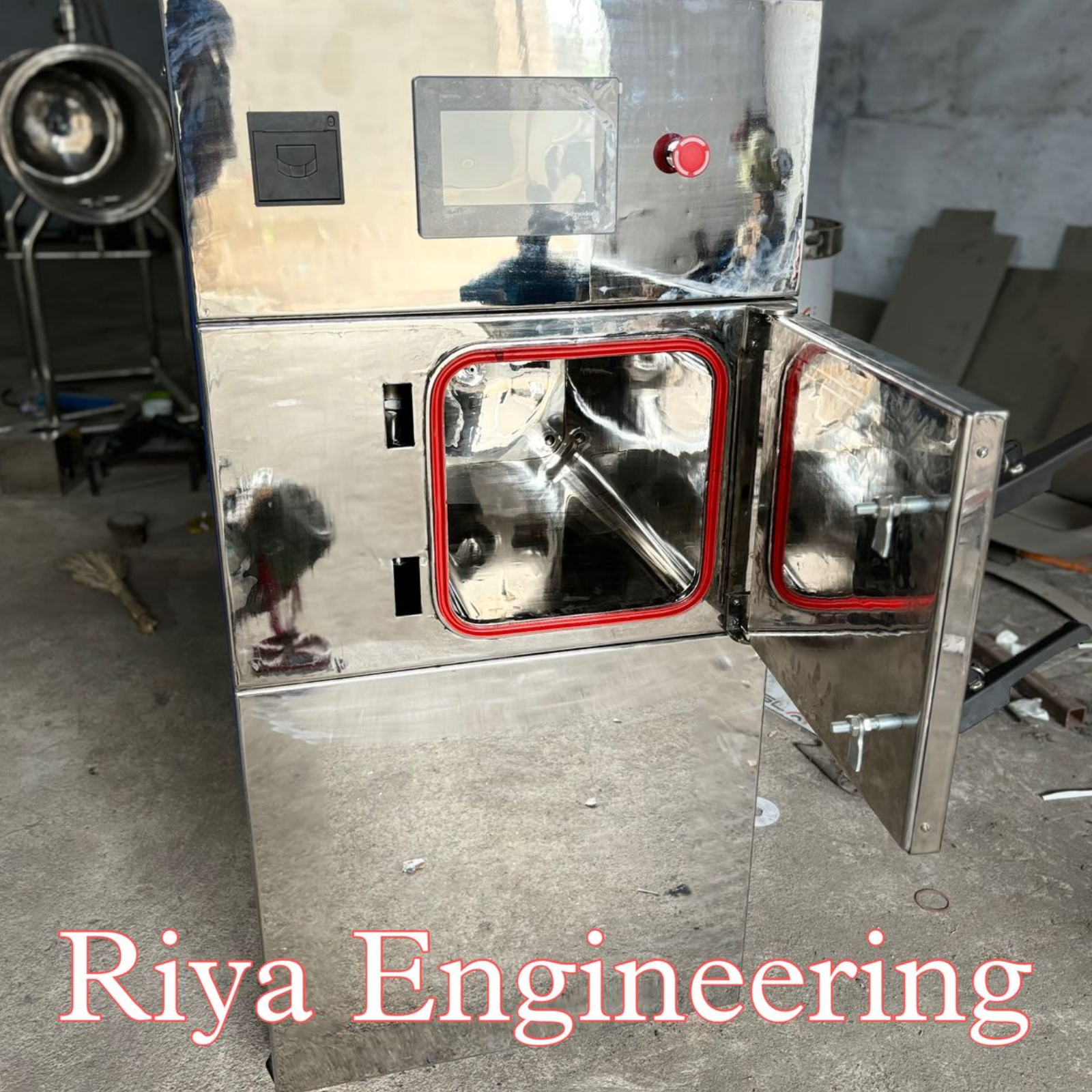

RIYA ENGINEERING ETO (Ethylene Oxide) sterilizer with dimensions 1x1x2 meters is a compact sterilization unit commonly used in hospitals and medical facilities for sterilizing heat- and moisture-sensitive medical devices. Here's an overview of such a unit: 🔹 What is an ETO Sterilizer? An ETO sterilizer uses ethylene oxide gas to sterilize medical equipment. It's especially useful for instruments that cannot withstand the high temperatures and moisture of steam sterilization (autoclaving). 🔹 1x1x2 m ETO Sterilizer – Key Features Chamber Size: 1m x 1m x 2m (Width x Height x Length ) – suitable for small to medium hospital loads. Sterilization Capacity: Ideal for surgical instruments, plastic devices, catheters, endoscopes, and electronic medical tools. Material Compatibility: Can sterilize rubber, plastics, electronics, and optics. 🔹 How It Works Pre-conditioning: Items are warmed and humidified to prepare for sterilization. Gas Exposure: Ethylene oxide gas is introduced and maintained under controlled temperature, pressure, and humidity. Aeration: Items are aerated to remove residual gas, ensuring they are safe for patient contact. 🔹 Advantages Low-temperature sterilization (ideal for delicate items). Penetrates packaging and device lumens. Effective against all known viruses, bacteria, and fungi. 🔹 Disadvantages Toxic and flammable gas – requires strict safety measures. Long cycle time (can range from 12 to 24 hours including aeration). Requires good ventilation and proper exhaust systems.

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Submit Your Enquiry